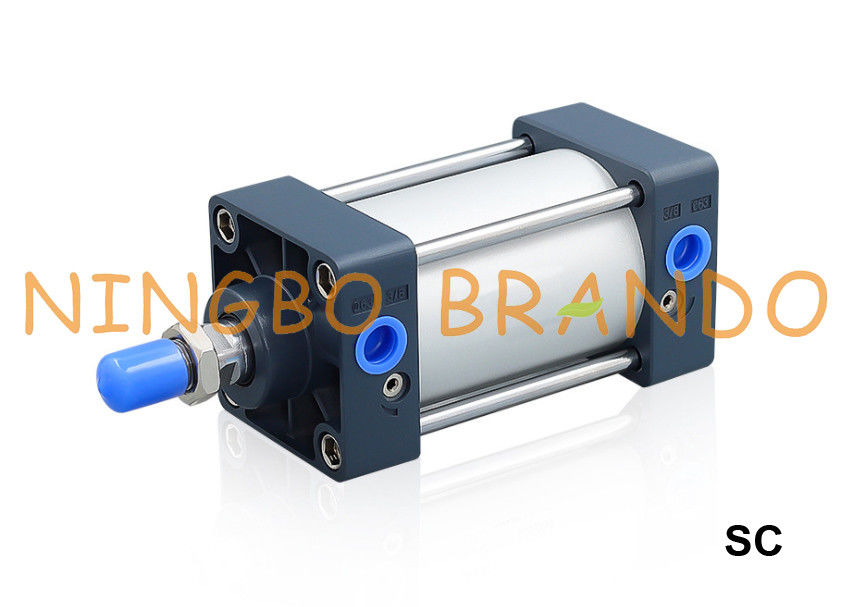

Airtac Type SC Series Pneumatic Air Cylinders Double Acting

In many industries, creation of a linear motion during an operation sequence is often required. A pneumatic cylinder, which is also referred to as an air cylinder, is one of the simplest, most cost-efficient solutions. Pneumatic cylinders are mechanical devices that convert the energy of compressed air to a linear motion.

Single-acting cylinders

Single-acting cylinders (SAC) use the pressure imparted by compressed air to create a driving force in one direction (usually out), and a spring to return to the "home" position. More often than not, this type of cylinder has limited extension due to the space the compressed spring takes up. Another downside to SACs is that part of the force produced by the cylinder is lost as it tries to push against the spring.

Double-acting cylinders

Double-acting cylinders (DAC) use the force of air to move in both extend and retract strokes. They have two ports to allow air in, one for outstroke and one for instroke. Stroke length for this design is not limited, however, the piston rod is more vulnerable to buckling and bending. Additional calculations should be performed as well.

Specifications of SC Series Pneumatic Cylinder:

| Bore Size (mm) |

32 |

40 |

50 |

63 |

80 |

100 |

125 |

160 |

200 |

250 |

| Acting Type |

Double Acting |

| Fluid |

Air (to be filtered by 40μm filter element) |

| Mounting Type |

SC |

Basic FA FB CA CB LB TC TCM1 |

| SCD, SCJ |

Basic FA LB TC TCM1 |

| Operating Pressure Range |

0.15 to 1.0 MPa (1.5 to 10.0 bar) (22 to 145 psi) |

| Proof Pressure |

1.5 MPa (15 bar) (215 psi) |

| Temprature (℃) |

-20 to +70 |

| Speed Range (mm/s) |

30 to 800 |

30 to 500 |

| Cushion Type |

Variable cushion |

| Adjustable Cushion Stroke (mm) |

21 |

28 |

29 |

36 |

40 |

| Port Size |

1/8'' |

1/4'' |

3/8'' |

1/2'' |

|

Stroke of SC Series Pneumatic Cylinder:

| Bore Size (mm) |

Standard Stroke (mm) |

Max. Standard Stroke |

Max. Stroke |

| 32 |

25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 |

1000 |

2000 |

| 40 |

25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500

600 700 800 900 1000

|

1200 |

2000 |

| 50 |

1200 |

2000 |

| 63 |

1500 |

2000 |

| 80 |

1500 |

2000 |

| 100 |

1500 |

2000 |

| 125 |

1200 |

2000 |

| 160 |

1500 |

2000 |

| 200 |

1500 |

2000 |

| 250 |

1500 |

2000 |

Symbol of SC Series Pneumatic Cylinder:

Ordering Code of SC Series Pneumatic Cylinder:

Criteria for selection: Cylinder thrust:

Installation & Usage:

1. When load changes in the work, the cylinder with abundant output capacity shall be ed.

2.Relative cylinder with high temperature resistance or corrosion resistance shall be chosen under the condition of high temperature or corrosion.

3.Necessary protection measure shall be taken in the environment with higher humidity, much dust or water drops, oil dust and welding dregs.

4.Dirty substances in the pipe must be eliminated before cylinder is connected with pipeline to prevent the entrance of particles into the cylinder.

5.The medium used by cylinder shall be filtered to 40μm or below.

6.Anti-freezing measure shall be adopted under low temperature environment to prevent moisture freezing.

7.The cylinder shall be carried out test run without load before application. Prior to run, buffer shall be turned to the minimum and gradually released to avoid the damage on cylinder caused by excessive impact.

8.The cylinder shall avoid the influence of side load in operation to maintain the normal work of cylinder and extend the service life.

9. If the cylinder is dismantled and stored for a long time, please conduct anti-rust treatment to the surface. Anti-dust caps shall be added in air inlet and outlet ports.

Focus on your demands, Offer you best solution:

√ Contact us if some points you have doubt

√ Contact us if somewhere need to change

√ Contact us if not the one you are looking for

√ Contact us if you are doing designing

Welcome to your any question and inquiry!

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!